Solutions

Energy Conservation

Magnation's Rainlike Water moves faster and further. With less friction, pumping energy savings are significant. Case Studies reflect 25% savings for Ag irrigation, and 42% reduction in pumping costs for HVAC. Energy conservation methods are multi-faceted, but none as elemental as addressing water quality issues to shave inefficiencies.

Reduce friction and viscosity for higher GPM's with less energy

Magnation’s specialized magnetic field decreases surface tension, reduces friction and viscosity (thickness) for faster and easier flow. With less resistance, water, fluids and air move more swiftly and with less energy. This impacts pump energy requirements significantly.

Reduce CO2 emissions, generate more RPM’s with less effort for higher efficiency and longer pump life.

With less mineral buildup on the interior of pipes, energy savings multiply and flow increases. Coupled with 20% less water needed whether for irrigation or blowdown, pumping energy savings can make a big impact in your bottom line.

- Energy savings 10-42%

- Solve mineral scale and corrosion without chemicals

- Extend equipment life and reduce downtime

- Reduced viscosity and friction

- Improve pump performance

- Better flow and pressure

- Reduce maintenance

- Less chemicals

- 2-year money-back guarantee

-

Improved flow with reduced energy

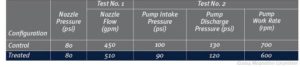

Controlled study performed by Marin County (California) Fire Department in 2009 shows Magnation’s water technology increased the water flow from 450 gallons per minute to 510 gpm—about 13.3% improved flow. It also decreased its pump intake pressure from 100 to 90 psi, pump discharge pressure from 130 to 120 psi, and the pump work rate from 700 to 600 psi. Nozzle pressure remained constant at 80psi .

-

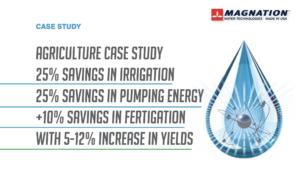

Agriculture Case Study: 25% less energy requirements for pivot irrigation

After installing the Turbulator on a standard quarter section (130 acres), Lee Fintel reported Magnation reduced water usage by 33% (2 acre-inches). The Turbulator saved 9 million gallons in water savings for a single year. Also, 200 hours of energy savings. Because less water was needed, there was reduced needs for the electric motors involved in the water pumping process, in addition to friction loss.

-

Case Study: 42% less energy requirements for HVAC with better water quality

“After installing Magnation, we observed 42% savings in energy, less scale formation, higher efficiency in cooling with less demand on compressors for cooling towers resulting in easier chilling cycles, better spray pattern on 15 year old equipment — the manufacturer had never seen that before! And, the cooling tower use to have a foul stink that no longer smells.”

~ Brian Malone, Chief Engineer at The GAP Headquarters, California, 2018

In addition to Magnation solving hard water issues and lowering pH, Malone noted a reduction in water and energy waste, Co2 emissions, and reaping evaporation credits from the City of Pleasanton— the only business to achieve this.

10-42%

Energy Savings

Pumping Water for Farms, Dairy, Ranches, Turfgrass Irrigation, Residential, HVAC, Industry? We have guaranteed solutions in the water-energy cross section, saving money, CO2 emissions, downtime, improving pump performance and extending equipment life.

- 2020 TOP PRODUCT Award from Environment + Energy LEADER

OUR PRODUCTS

We offer a wide range of energy saving water conditioning products for all water-using applications

Speak with a Water Consultant

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Let's Talk