Magnation boosts yields using less water and energy, despite drought

25% less water, 25% reduced energy, rapid and even crop growth, 10% reduced fertigation, with 10% increased yields in drought struck Nebraska

Lee Fintel owns and farms 6,200 acres of corn and soy spanning three counties between Nebraska and Kansas. The Fintel farm includes 23 pivots and one subsurface drip irrigation system over 49 fields. Fintel Farms produces approximately 600,000 bushels of corn and 200,000 bushels of soybeans annually.

As a board member of the Bostwick Irrigation District in the Lower Republican Natural Resources District (NRD) bordering Nebraska and Kansas, Lee Fintel is a prime example of resource stewardship, advocating a lower impact on the environment while yielding higher and smarter. With engineer-minded data sets for almost a decade after installing Magnation, this cutting-edge Pro Farmer understands the critical choices made in Agriculture to assure a profitable season, year after year.

Fintel’s primary focus is to transform problematic high salt water into hydrating, productive water and improve the soil pH to insure a better harvest each season. Saline soils due to high saline water and continual buildup is a global issue. This is no exception in Nebraska, where water is drawn from both surface and groundwater.

Overview

In 2013, Lee Fintel installed a Magnation Turbulator in the irrigation system on one of their farms to help with water infiltration capacity and soil health. This particular farm has always had a challenging soil pH level in the mid 8’s. Water was from a surface source. Soil tests are conducted on all Fintel farms annually. After the first year of irrigating with the Magnation treated water, pH levels improved. Due to the corrective influence on the water from the Turbulator, during the period from 2013 to 2021, the soil pH level has improved from 8.3 to 7.3 on that farm.

Methodology

Each fall a professional agronomist takes a soil sample (4’ probe) from the same spot in the field using GPS to pinpoint the spot. The sample of dirt is then sent to a lab for analysis of content of nutrients, trace minerals, pH, etc.

Results – With Magnation Involvement

Starting at pH 8.3, Magnation has brought this down to 7.3 by 2021. The simple compounding impact has generated healthy soil with zero chemicals, zero extra labor, and zero maintenance.

• 25 percent less fertilizer was required. As water on the farm became softer and more bioavailable via the Turbulator, less fertilizer was required. Put simply, the plants used nearly all of the water and not just some— and because the plants could take up more water, fertilizer was also more easily absorbed. Thus, less fertilizer is needed to get the job done.

• Seeds became more effective and crops grew more efficiently. It was also discovered that by running seeds through the Turbulator the process would “wake” them up so that they could grow faster, more evenly and efficiently. This is extremely important because the faster a seed can grow, the less water that’s needed. Additionally, the more even a crop, the better for overall yield and success.

Conclusion

“Our results have been remarkable,” says Fintel. “Where we installed the Magnation unit, the corn out-yielded our other irrigated corn but used 30% less irrigation water. The corn was 11% better than that field’s previous best yield, there was noticeably better uniformity across the sprinklers on the pivot, and our pumping costs were lower.”

These findings offer huge implications to farmers across the country and around the world, especially in the face of decreased rainfall, drought, and increased global temperatures.

“Not only do Magnation’s technologies help farmers save, they allow for us to offer healthier produce for consumers. Higher quality water means higher quality crops. And this translates to a healthier, more nourished population,”

says Fintel.

Testimonial

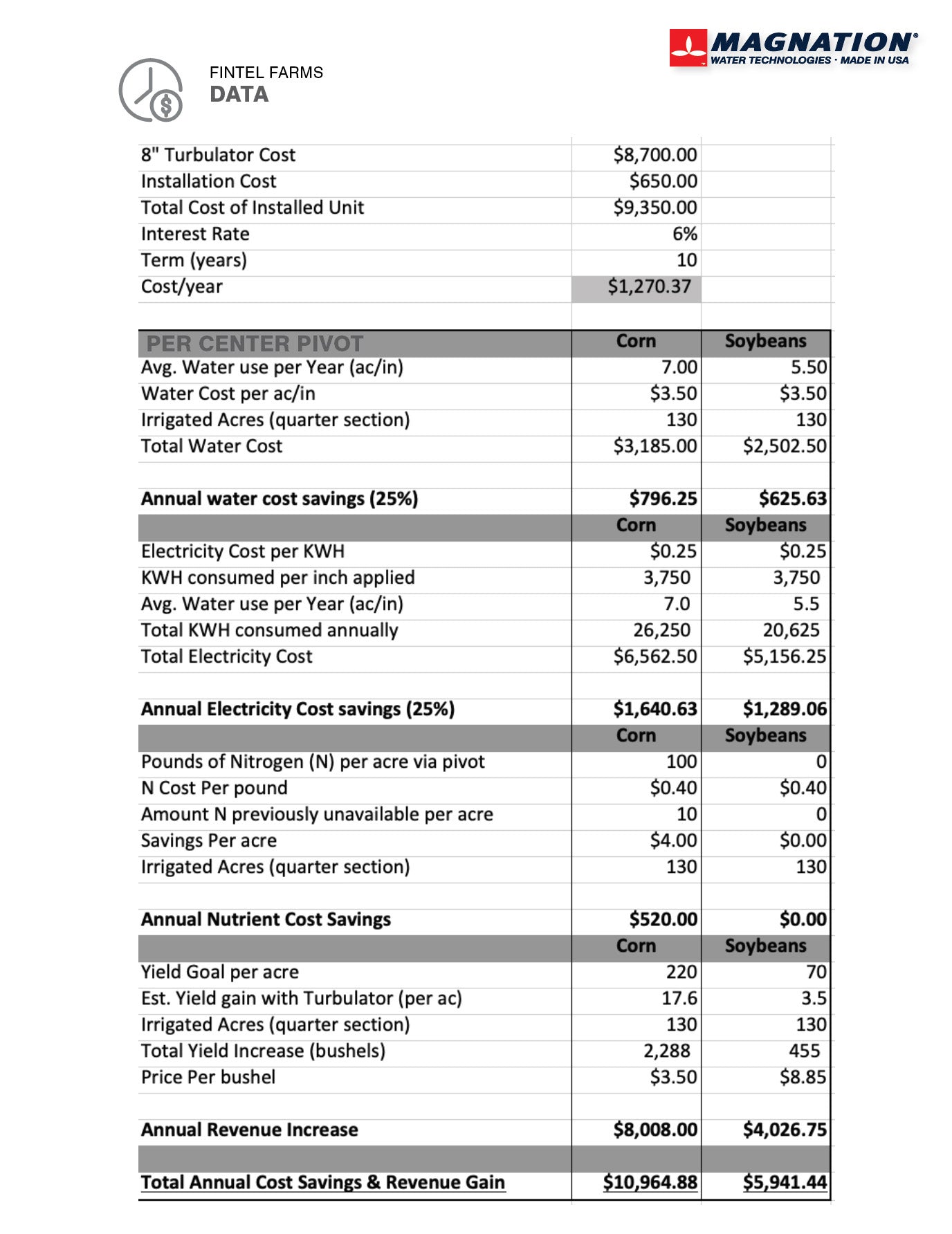

“Our results have been remarkable. In a typical year in Central Nebraska we would pump 7 acre inches of irrigation water on our corn crop, and assuming a standard quarter section pivot. Using the field proven conservative 25% savings in irrigation requirements once the Turbulator is installed in the system, the amount of water we save annually is huge. Using one of my pivots as the example, the math looks like this:

Application time per inch pumping 550 gal/min – 100 hrs.

550 gal/min x 60 min/hr x 100 hrs = 3,300,000 gal per acre inch applied

7 ac/in x 3,300,000 = 23,100,000 gallons per season

Saving 25% water by using the Turbulator equals 5,313,000 gallons saved per pivot. In a typical year we will have 5 pivot quarters of corn, so we will conserve over 26M gallons of water, annually. Taking a look at cost per gallon of water saved, a Turbulator costs 1/1,000 of a cent per gallon, annually. Over 10 years that would be 1/10,000 cent per gallon. In addition, we save 25% of our pumping costs. Our corn yield increased by 10%, and our soybeans by 5%.”

~ Lee Fintel, Fintel Farms, Superior, Nebraska, US