Fintel Farms Saves Water and Yields Bigger. Fast ROI

Facing a lack of water, Fintel Farms from Superior, Nebraska increased crop yield by 48 bushels per acre using 33% less water

Nebraska comes by its nickname, The Cornhusker State, honestly. According to the U.S. Department of Agriculture, 10.3 million acres of corn are expected to be planted in the state during this year’s growing season, alone. Almost 98 percent of the state is farmland. That’s 45.6 million acres of land that produce not only corn, but also soybeans, grain sorghum, dry edible beans, wheat, alfalfa and hay, potatoes and sugar beets, all grown and brought to market via the state’s 47,200 producing farms. Accordingly, water is a very closely monitored, often disputed and highly valued resource.

Lee Fintel, owner of Fintel Farms in Superior, Nebraska, knows only too well what a precious natural resource water is. Fintel bought his first farm in 1987, shortly after he finished college. Today he owns and operates 1400 acres of farmland, with seasonal help during harvest time. The corn and soybeans from Fintel’s farms are sold primarily to grain merchandisers in local co-ops. Like those of so many other Nebraska farmers, Fintel’s business depends on the availability of water and the effectiveness of that water.

Facing a lack of water: one farmer’s dilemma

Fintel states that in Nebraska, farm irrigation water is typically accessed in two ways. “One way is to take it from surface water supplies, such as an existing lake or body of water, the other is to pump it from sub-surface ground water aquifers.” Each year, the state’s governing bodies determine how many acre inches of water farmers can legally use for the season. “For instance,” said Fintel, “this year we’ve been given an allocation of 13 acre inches. But even though I have the legal right to use that much, my wells, on one or more of my farms, don’t have the volume capacity to pump that much water. I have one farm where the capacity of my well is only 370 gallons a minute. It would have to produce double that amount to provide the volume of water that’s typically needed during my growing season.”

Fintel knew that there was nothing he could do to get his well to pump more water. “That’s all the water there is at that location.” What he needed was something that would make the water that was available, more efficient and more usable for the crops. Several years ago, he began looking for a cost-effective way to solve this problem.

“I am pretty thorough when I research new things; I’m a farmer but I also managed and was a partner in an engineering and project management firm for nearly 30 years. When I make an investment, I expect results,” said Fintel. “I began with some preliminary research and found that I could use products like wetting agents. But that’s something you need to continually purchase and inject into your water. I was hoping to find something less time and labor intensive.” When Fintel attended the annual Husker Harvest Days conference, his curiosity was piqued by a solution that claimed to address his problem without chemicals, without time and maintenance and, moreover, without a large financial investment. That solution was Magnation Water Technologies’ water treatment products.

Making the decision to try something new

Fintel eventually decided to purchase Magnation’s solution, but not before he did months’ worth of due diligence about the effects of magnetized water on soil and crops. “I looked for unbiased University and scientific community studies and real world test results that backed up the company’s claims,” said Fintel. “Then I asked for references and I talked to people who were using Magnation products. I became more and more convinced that this was a viable option for me to consider. I then reviewed competitors’ products to make sure I was going to use the best out there.”

What Fintel discovered was that the Magnation water treatment solution is the only such product on the market that is engineered specifically for a variety of applications. “There were other similar products and some that used an ELECTRO-magnetic field, but they required electricity, energy consumption that would increase production costs,” said Fintel. “Magnation doesn’t need any energy source and I like that it requires no ongoing maintenance.” Ultimately, Fintel concluded that the highest quality, best (only) engineered water treatment solution he could buy was Magnation. “At that point,” said Fintel, “I was very confident in making the investment.”

Putting Magnation to the test

Fintel purchased his first Magnation irrigation water treatment unit in early 2013, but when the post pump irrigation unit was installed, he wasn’t simply content to say “okay, I’m done with that,” and walk away from it. He believed that he would never really know or understand the benefits of this solution unless he monitored what was happening. He felt strongly that he needed to conduct a comparative test to see exactly how much of a benefit the Magnation treatment offered.

“If you have a water treatment unit installed in your irrigation system and your corn crop produces 250 bushels per acre, how are you going to know what it would have produced without it if you’ve watered all of your acres with treated water?” questioned Fintel. For that reason, Fintel set up what he considered to be a scientific study of two of his farms, West and East. Both one-quarter section farms had corners of non-irrigated land around a larger portion of land that was irrigated. On the West farm, the irrigated land was watered with the use of a Magnation water treatment unit; on the East farm the irrigated portion used water that was untreated. Both farms are primarily class-one soils and have been gridded and trace-mineral optimized. Both have been no-till farmed for at least 12 years; they were planted on back to back days with the same hybrid, with the same population. On both farms the crops were treated with fungicide.

According to Fintel, “These farms were essentially the same, except that on the West farm the water for the irrigated portion was treated through a Magnation unit. I worked with an independent agronomist and followed his recommendations to a tee. We tracked the two farms for two years: We charted two years’ worth of rain fall, we probed weekly for soil moisture content from the start of the growing season to the end of the growing season; the crops were watered exactly as our consultant advised.

After two years of monitoring the farms, the results were extremely impressive to Fintel. “There was significant difference in what I call the ‘advancement’ of the crop yield in the Magnation irrigated part of the West farm.“

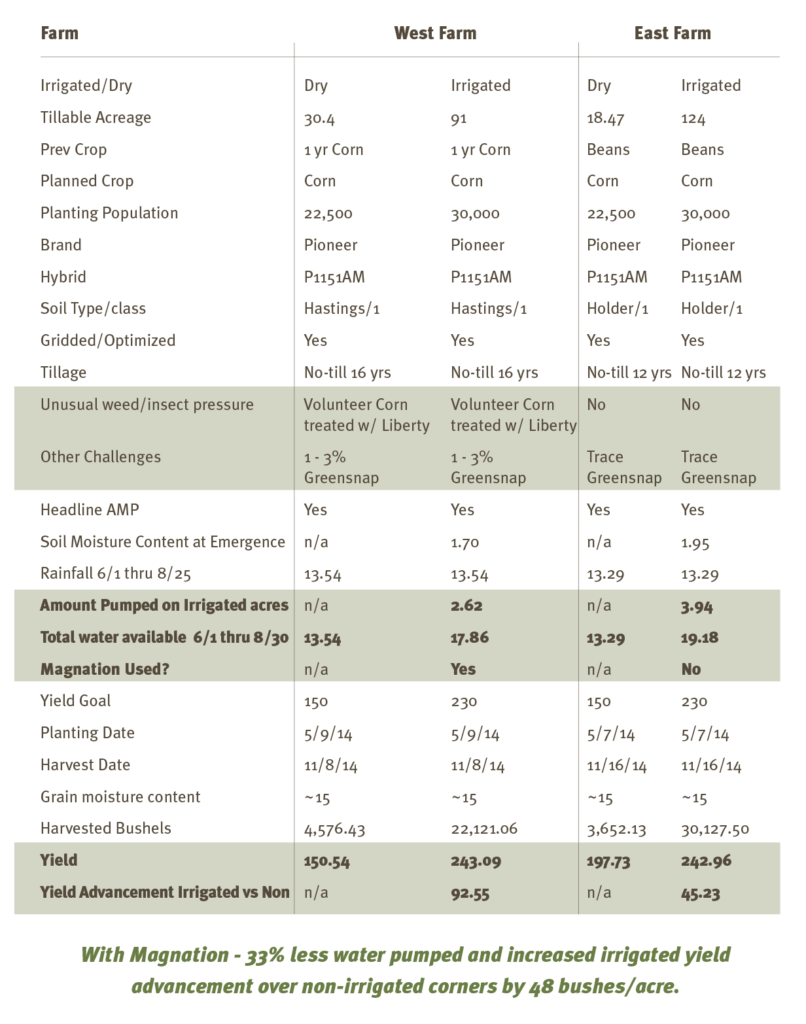

The following table is a side by side comparison of the two farms, detailing all of the variables accounted for in the study. Fintel emphasizes key items that are highlighted, such as The Amount Pumped and Total Water available through the growing season. For the West Farm, 17.8 inches were available; the East farm had 19.17 inches of water available, the difference due to variable rainfall and the amount of irrigation water pumped. “We conducted weekly probes that showed the amount of soil moisture in the top three feet, beginning at emergence … so we know that those numbers are exactly right,” said Fintel. The yield for the non-irrigated part of the West farm produced 150.54 bushels per acre. The Magnation-treated, irrigated part of West produced 243.09 bushels per acre.

“At first it may seem that there was no difference in yield between the two farms,” said Fintel. “But what you need to look at, and what convinced me that the Magnation-treated water was effective, was the difference between the “Dry” and “Irrigated” production in each case.” On the West farm, the Magnation-treated irrigated land yielded 61.5% more than the non-irrigated land (the difference between 150.5 and 243 bushels). On the East farm, the non-treated irrigated land yielded only 22.7% more than the non-irrigated land (the difference between 198 and 243 bushels). “The Magnation-treated irrigation water advanced us 93 bushels per acre over the non-irrigated corners on the West farm,” said Fintel. “On the East farm, the non-treated irrigation water advanced us only 45 bushels per acre and we needed 33% more irrigation water.”

Another significant variable is that the West farm experienced green snap pressure and volunteer corn pressure (hardships to the crop), the East farm did not. Despite less rainfall and the hardships to the crop, Fintel was still able to advance the Magnation-treated irrigated production by roughly 2 times. The Magnation-treated West farm came out significantly ahead: 93 versus 45 bushels per acre.

The Magnation Effect: Percentages Speak Volumes

“Some may look at this data and suggest that the outcome was because of other variables, and to them I offer this response,” said Fintel. “Let’s say we only attribute half of that positive outcome to the Magnation water treatment – that would be an advance of about 25 bushels an acre. Just multiply those 25 bushels per acre by the $4.00 per bushel corn you get from the crop. That’s means you’d get $100 more per acre. For 90 acres, at minimum, I got $9,000 more for those crops. That’s twice as much as what my Magnation system cost. So, it paid for itself twice over by the second year I was using it.”

Fintel is now a firm believer in the Magnation water treatment system. “I’m a hard guy to convince,” said Fintel, “but I have more than enough tangible evidence to prove that the Magnation water treatment systems really work. We all have an obligation and a responsibility to protect our most precious natural resource – water – for now and for future generations. We’re all in business to be profitable, but along the path to profitability we must be responsible stewards and operate in a sustainable fashion for the future. I feel that any potential solutions need to be considered. I believe that Magnation is one such solution; an example of where innovative thinking provides bottom-line results.”

Speak with a Water Consultant

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Let's Talk