42% energy savings for HVAC at The Gap

Magnation affirmed solution by engineers at The Gap Inc. 5-story commercial building, saving 42% energy and water with less blowdown and evap credits

Brian Malone is the chief engineer at the Gap headquarters in Pleasanton, California and assures efficient maintenance operations for the 180,000 square feet five-story facility. The Gap was looking to solve its exceptionally hard water problems, and Malone meticulously collected data to understand the impact Magnation would deliver.

Magnation’s devices were promised to decrease surface tension, reduce friction and viscosity for faster and easier flow. Magnation also improves pump performance with better air intake, better spray patterns, and flow inducement while saving fuel to get more power with less energy and maintenance. Malone was eager to see if water works more effectively when conditioned with Magnation, in hopes of positively.

Why Did The Company Work With Magnation?

The water source has high pH, high TDS and is hard. Hardness as CaCO3 in the groundwater ranges from 316mg/L up to 529 mg/L. These numbers impact water consumption with excessive

evaporation and water waste, increased energy bills, and higher Co2 emissions. Additionally, a foul smell from hydrogen sulfate was problematic, and high pH was eroding equipment.

Solution

A combination of Magnation Rainbolts (2-stage treatment with magnetic resonance treatment) Aquabolts (5 stage treatment consisting of double Rainbolt and vortexing treatment) were installed throughout the facility. Magnation units were installed on the incoming main line, boilers, cooling towers, ice makers, and drinking fountains.

Results – With Magnation Involvement

In addition to solving hard water issues and lowering the pH, Malone noted a reduction in water and energy waste, Co2 emissions, and reaping evaporation credits from the City of Pleasanton— the only business to achieve this.

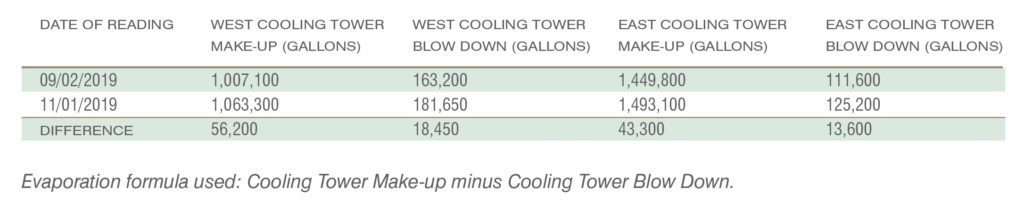

Evaporation was reduced by 37,750 gallons in the West Cooling Tower, and 29,700 gallons in the East Cooling Tower. The difference of two months worth of data equated to a savings of 67,450 gallons of water. Expected savings will approach half a million gallons of water per year in water savings alone.

Conclusion

Magnation is an effective treatment for scale prevention as it reduces precipitation on solid surfaces. As a chemical-free water descaler for commercial, industrial and residential applications, Magnation reduced total dissolved solids (TDS), reduced need for expensive and damaging chemicals, and used 42% less energy for HVAC pumping. Reduction of 42% in energy consumption due to two factors: using less water and reduced friction from less surface tension of the water.

Blow down reduced by 10%, saving water and the company received evaporation credits from the City of Pleasanton.

Speak with a Water Consultant

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Let's Talk