Magnation boosts yields using less water and energy, despite drought

25% less water, 25% reduced energy, rapid and even crop growth, 10% reduced fertigation... with 10% increased yields in drought struck Nebraska. Let's talk food security with changing climates. Click to read!

Overview

The State of Nebraska sees 10.3 million acres of corn planted yearly, and almost 98 percent of the state is farmland. This equates to 45.6 million acres of land that primarily grows corn, soybeans, grain sorghum, dry edible beans, wheat, alfalfa, hay, potatoes, sugar beets, and more. There’s a huge demand for water, which is very closely monitored and often disputed due to drought.

Like many other farming areas around the world, Nebraska is faced with numerous challenges as farmers cope with changes in climate, intensification of floods and droughts, depletion of resources, and rising water and energy costs. Over the next 40 years, the world population is expected to grow beyond 9 billion people, which makes innovation and the ability to evolve farming practices paramount.

In an effort to help lead the way in innovation, Lee Fintel, owner of Fintel Farms in Superior, Nebraska has been working to find creative solutions for making farming more sustainable. He knows too well how precious and expensive water is in today’s world.

Magnation Water Technologies uses the laws of physics to help farmers save time, money, and resources in their effort to keep the food supply healthy and plentiful.

In the following case study, we’ll examine how Magnation helped Fintel Farms accomplish four important goals:

(1) Reduced water costs and usage

(2) Reduced energy costs and usage

(3) Rapid and even crop growth

(4) Reduced fertigation

Solution

Fintel decided to consult with Magnation Water Technologies to find creative solutions for their water shortage issues. “We were looking for something out of the box — a way to make water more bioavailable, to reduce water and energy costs, and to even find ways to make our seeds and planting methods more effective,” says Fintel.

Magnation suggested he try a Magnation Turbulator to better capitalize on the water the farm has access to. Additionally, Fintel hoped that by using Magnation’s technology he could take his conservation efforts further by reducing the amount of water needed, reducing energy costs, and making crop growing efforts more efficient.

Magnation’s powerful Turbulator transforms previously unusable water to a soft, productive and energized state. Turbulator is designed with ultra-boosted top-grade magnetic resonators and innovative engineering to significantly improve water quality.

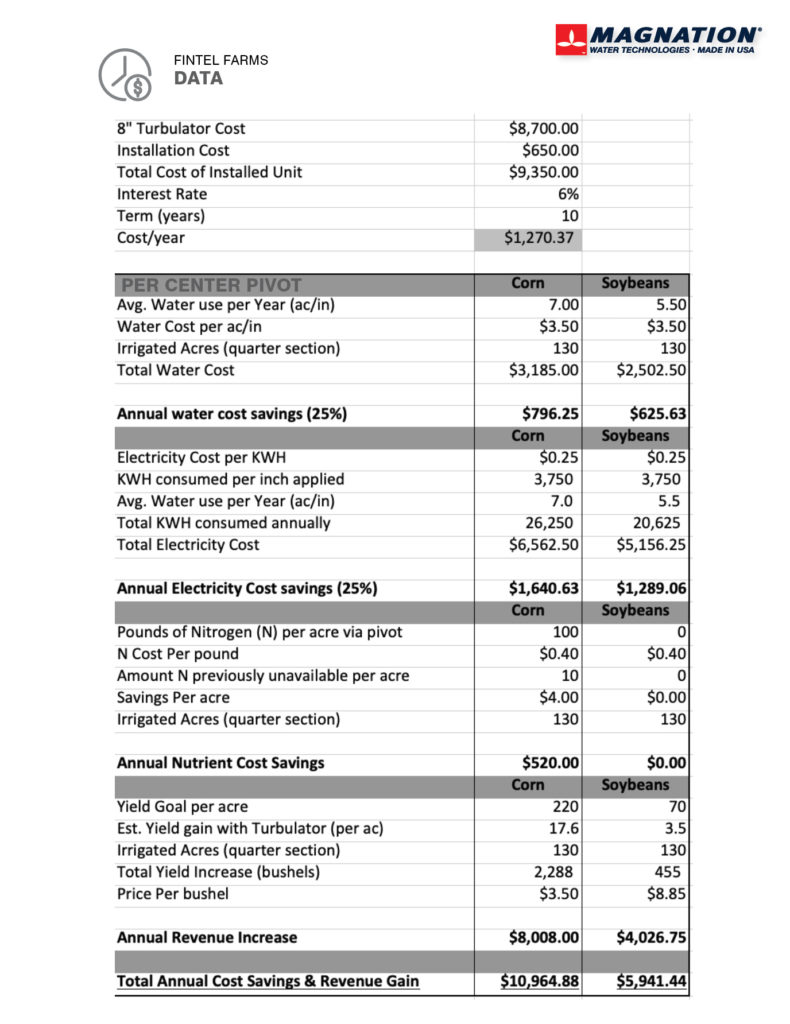

After installing the Turbulator on a standard quarter section (130 acres), Fintel reported powerful data at the end of the growing season:

• Magnation was able to reduce water usage by 33% (2 acre-inches). The Turbulator made the water more bioavailable, which led to roughly 9 million gallons in water savings for a year. This translates to between 25-30 percent savings year over year!

• About 200 hours of energy savings. Because less water was needed, there was reduced needs for the electric motors involved in the water pumping process.

• 25 percent less fertilizer was required. As water on the farm became softer and more bioavailable via the Turbulator, less fertilizer was required. Put simply, the plants used nearly all of the water and not just some— and because the plants could take up more water, fertilizer was also more easily absorbed. Thus, less fertilizer is needed to get the job done.

• Seeds became more effective and crops grew more efficiently. It was also discovered that by running seeds through the Turbulator the process would “wake” them up so that they could grow faster, more evenly and efficiently. This is extremely important because the faster a seed can grow, the less water that’s needed. Additionally, the more even a crop, the better for overall yield and success.

Conclusion

“Our results have been remarkable,” says Fintel. “Where we installed the Magnation unit, the corn out-yielded our other irrigated corn but used 30% less irrigation water. The corn was 11% better than that field’s previous best yield, there was noticeably better uniformity across the sprinklers on the pivot, and our pumping costs were lower.”

These findings offer huge implications to farmers across the country and around the world, especially in the face of decreased rainfall, drought, and increased global temperatures.

“Not only do Magnation’s technologies help farmers save, they allow for us to offer healthier produce for consumers. Higher quality water means higher quality crops. And this translates to a healthier, more nourished population,” says Fintel.

Testimonial

“Our results have been remarkable. In a typical year in Central Nebraska we would pump 7 acre inches of irrigation water on our corn crop, and assuming a standard quarter section pivot. Using the field proven conservative 25% savings in irrigation requirements once the Turbulator is installed in the system, the amount of water we save annually is huge. Using one of my pivots as the example, the math looks like this:

Application time per inch pumping 550 gal/min – 100 hrs.

550 gal/min x 60 min/hr x 100 hrs = 3,300,000 gal per acre inch applied

7 ac/in x 3,300,000 = 23,100,000 gallons per seasonSaving 25% water by using the Turbulator equals 5,313,000 gallons saved per pivot. In a typical year we will have 5 pivot quarters of corn, so we will conserve over 26M gallons of water, annually. Taking a look at cost per gallon of water saved, a Turbulator costs 1/1,000 of a cent per gallon, annually. Over 10 years that would be 1/10,000 cent per gallon. In addition, we save 25% of our pumping costs. Our corn yield increased by 10%, and our soybeans by 5%.”

~ Lee Fintel, Fintel Farms, Superior, Nebraska, USA

Speak with a Water Consultant

Our representatives have a wealth of knowledge on all our products – let them steer you in the right direction.

Let's Talk